Firetrace Automatic Fire Suppression Systems are self-activating extinguishing systems. Firetrace utilizes a reliable and highly effective detection tubing to detect and extinguish fires in seconds, where and when it starts.

Firetrace is completely self-contained, it does not require electrical power and remain operational during power outages. It is a concept providing first line of defence that extinguishes fire quickly within the protected space. With this, a growing fire can be mitigated, preventing the spread of fire to other parts of the equipment, room or even the building. As a result, fire damage, costs associated with clean-up and downtime are significantly reduced.

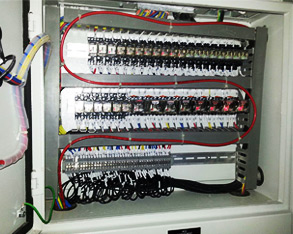

Designed for simple installation, Firetrace systems can be installed in any enclosed space, often near to the source of potential fire. Firetrace is a cost-effective solution to the problem of “micro-environment” fire protection, where the hazard is typically contained within a critical enclosure that is beyond the reach of conventional fire suppression and alarm systems. It is particularly suitable to be installed in electrical equipment, machines, vehicles, storage compartments, etc.

Firetrace Detection Tubing combines leak resistance, flexibility, durability and precise temperature sensitivity, allowing it to react quickly when the heat from a fire is present. It is designed to rupture when exposed to a fire’s radiant heat, which automatically triggers the release of the fire extinguishing agent.

Firetrace systems are compatible with most commercially available fire suppression agents, including :

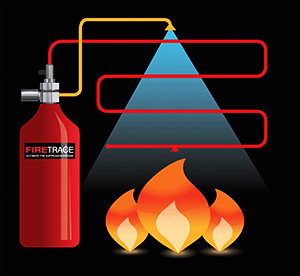

The Direct Release System utilizes the Firetrace Detection Tubing as both the fire detecting sensor and extinguishment delivery device.

In the event of a fire, the portion of the tube nearest the hottest point of the fire ruptures, forming a discharge “nozzle”. The pressure drop in the tube releases the entire contents of the cylinder through this nozzle, extinguishing the fire where it starts.

With the Indirect Release System, the Firetrace Detection Tubing is used as a detection-only device.

When the tubing ruptures the pressure is released, allowing the valve to operate and release the extinguishing agent through a separate network of braided hose or copper/stainless steel tubing to one or more strategically placed nozzles within the protected enclosure.

Major listings and approvals from UL, ULC, FM, CE and etc., and supported by a network of over 250 distributors worldwide, Firetrace has more than 150,000 systems installed, protecting critical equipment worldwide, including:

Data centres, communications & UPS cabinets, medical equipment, switchgears, transformers.

EDM machines, enclosed automated milling machines, welding machines, plastic injection moulding machines.

Forklifts, paper pulping machines, mobile cargo equipment, plant machinery.

Chemical storage & production, R&D labs, pharmaceutical labs, university & school labs.

Electric trains, buses, emergency vehicles, airport control towers.